2019-08-08

On December 13th, 2018, Daye Special Steel combine with Shenzhen Mould Technology Association, held the application technology Seminar of Daye Special Steel Die Steel in Foshan Intercontinental Hotel. The conference was hosted by Daye Special Steel Co., Ltd., assisted by Guangdong Strong Metal Technology Co., Ltd., and STRONG was also the general agent of Daye High-end Die Steel in South China. The participating units include Guangdong Wencan Mould Co., Ltd. and Guangdong Hongtu Technology Co., Ltd., and more than 70 well-known mold manufacturers in South China. Daye Special Steel is one of the largest special steel producers in production, and the tool and Die steel products have been recognized by large domestic and foreign enterprises.

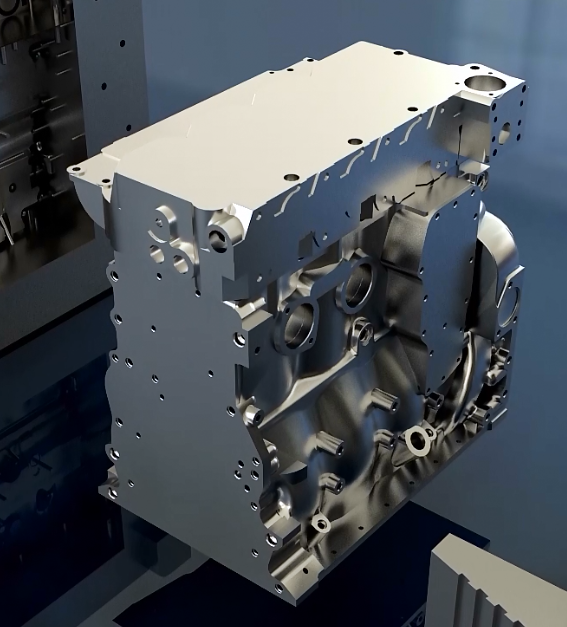

Daye Special Steel's high-end die-casting die steel combined with STRONG Technology's heat treatment, its material organization is uniform, high purity, good isotropic performance, high toughness, etc., deeply loved by users.

Mr. Liang Hang, the deputy general manager of STRONG Technology, focused on heat treatment of materials for nearly 30 years. He shared his expertise with the mold manufacturing unit of South China in the high-end die-casting die steel of Daye Special Steel.

The meeting was a small professional meeting with strong professionalism. The participants were much more than expected, and the small conference room was packed. Many mold manufacturers carefully listened to the mold professional report, unraveled the confusion of heat treatment in the production process, and improved the importance of using mold materials and heat treatment.

Mr. Zhang Yongqiang, Director of the Special Metallurgical Forging Research Institute, and Engineer as well as Director of Die Steel Research Office of Daye Special Steel Co., Ltd, introduced die casting die steel.

South China University of Technology, National Metal Materials Near Net Forming Technology Research Center; Mr. Zhao Haidong, Deputy General Manager of Foshan Nanhai Ben Mould Co., Ltd., made a wonderful analysis report on the corrosion causes of low-pressure casting aluminum alloy wheel molds.

Lu Hanming, Chairman of STRONG Technology; and Dong Xiaohong, General Manager of STRONG Technology, were invited to special guest.

Made by Special steel Daye, Served coming from STRONG!