2020-05-07

In order to promote the discipline development and technological progress in heat treatment and surface engineering, and promote the development of new material industry and high-end manufacturing industry. The biennial "National Academic Symposium on Heat Treatment and Surface Engineering of 14 Provinces and Cities" was successfully held in Chongqing on August 24th. The forum is not only an important platform for linking up exchanges and interactions among heat treatment industries in different regions, but also an important link between enterprises and research institutes. Professor Yin Fuxing from Hebei University of Technology and Professor Gu Jianfeng from Shanghai Jiaotong University share their knowledge and experience.

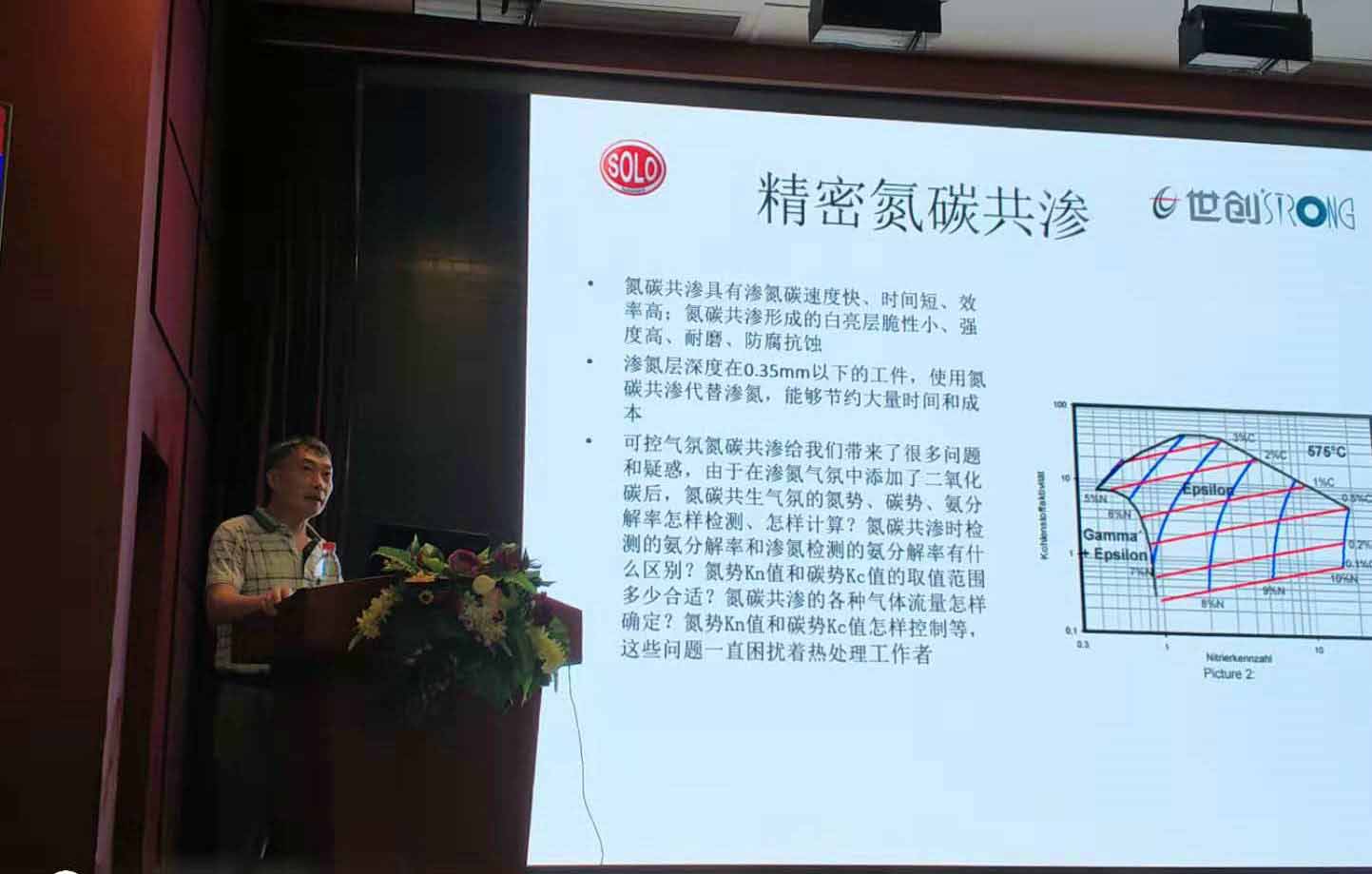

STRONG TECHNOLOGY has established a perfect mode of University-Enterprise Cooperation in scientific research, which combines industry, education and research. It has cooperated deeply with well-known universities at home and abroad for more than ten years. In response to the call of the conference, STRONG TECHNOLOGY went to the conference with the most subversive Bell-type nitriding furnace, which became one of the highlights of the conference. Yin Hanqi, Senior Engineer of STRONG TECHNOLOGY, was invited to give a report on the theme of precision nitriding technology and share the precise nitriding and nitrocarburizing technology developed by STRONG. The Bell type nitriding furnace developed by STRONG TECHNOLOGY and SOLO Swiss optimizes the process according to the technical requirements of nitriding and nitrocarburizing, and has excellent performance of high intelligence, safety, flexibility, energy saving and environmental protection. The biggest innovation of the equipment is the application of intelligent lifting mode, replacing the previous hook mode, which greatly saves energy consumption and site for the factory.

Bell type nitriding furnace has excellent performance of high intelligence, safety, flexibility, energy saving and environmental protection. It has revolutionary significance in the field of metal processing. Its outstanding innovative function modules and unique heat treatment process advantages are obvious: The highly intelligent software developed in cooperation with SOLO Swiss, which has the functions of energy consumption, abrasive wear and tear, equipment maintenance and spare parts replacement management; Precision nitriding and nitrocarburizing processes are carried out according to AMS2759/10A and 2759/12A standards in the United States. Vacuum pulse nitriding and oxidation after nitriding or carburizing are also carried out.