2020-07-15

Unique ion beam assisted deposition technology of STRONG TECHNOLOGY

Unique ion beam assisted deposition technology of STRONG TECHNOLOGY

Ion beam assisted deposition technology (STRONG ion source system), originates from the achievements of Sino-Russian coating science and technology cooperation. The basic principle of the system is that in the process of gas ion etching and cleaning, a pair of cathode arc targets for deposition are used to form a pair of cathode targets and anode targets in series by switching the arc power supply through the control circuit. The anode target is equipped with a baffle device in front of which only gas ions are allowed to pass through, forming an ion source system. According to the size of vacuum chamber and the quantity of arc target, one or more ion source systems can be set up in the system, which can be distributed according to the demand of high and low, so as to reach the requirement of uniform coverage of effective working area. The intensity of ion source gas ion etching can be adjusted by controlling the input power of arc power supply. In the process of deposition, each target is switched back to the cathode target for normal use. The switching between deposited cathode target and ion source system target is automatically switched by computer program in the process flow setting, and fully automatic operation.

At present, the system has applied for the national patent "a multifunctional plasma enhanced coating system" patent No. 201220594109.9. According to the investigation and feedback of SC1300 aviation blade coating machine of STRONG used by users of Xi'an 430 plant, the structure ion source can improve the etching and cleaning effect of workpiece surface, and the coating adhesion after deposition is better.

STRONG ion source system | Conventional rectangular ion source system |

It can be realized by using the original cathode target of arc plating with simple structure. | A set of ion source and power supply shall be specially configured. |

According to the needs of the working area, the ion source can arrange each pair of cathode anode targets in multiple directions of the equipment, so that the gas plasma can penetrate the whole working area evenly, and the gas ionization rate is higher than that of the conventional gas ion source. When entering the deposition stage, each target is switched back to the cathode target for deposition. | It can only be arranged on one side of the height direction of the equipment, which affects the uniform arrangement of cathode targets for deposition. Gas plasma can only be emitted from one direction, and the etching uniformity of the workpiece is poor. The gas ionization rate is low. |

It does not need to occupy the space of the vacuum chamber to install the conventional gas ion source. It can maximize the use of the vacuum chamber to install the arc target and improve the deposition rate. | The cathode target for deposition can only be reduced if it needs to be installed at a single location, which has an impact on deposition rate and uniformity |

Using arc power supply seat ion source power supply, no need for additional ion source power supply, simple operation, high reliability. | Ion source and power supply shall be provided separately |

In addition to the function of ion etching and cleaning, it can also realize a variety of characteristic processes such as ion nitriding, plasma enhanced deposition, etc. | It can only be used as ion etching cleaning function, with single function |

Equipped with multiple groups of ion sources, the failure rate of gas ion etching cleaning process section is greatly reduced. | As only one ion source is equipped, once the failure occurs, the whole gas ion etching cleaning process section will stop. |

Compared with the conventional coating, the advantages of using the STRONG ion source coating

Target utilization rate of STRONG coating equipment is more than 80%

In the production process of vacuum plasma arc plating, the target is a kind of consumables with high cost, especially the target made of some valuable materials, which is expensive. If the utilization rate of the target is not high in the process of using only, the waste is very amazing, and the production cost of the product is increased.

There is a problem in the traditional circular arc target technology, that is, the edge arc spots of the target working face are seldom ablated, and the target surface is ablated in the shape of pot bottom concave, so the utilization rate of the target material is very low; at present, the utilization rate of the target material of most equipment is no more than 50%. At the same time, artificial observation and manual adjustment should be carried out frequently, which is not conducive to the continuous operation of coating equipment for a long time.

The vacuum plasma coating machine of STRONG TECHNOLOGY is jointly researched and developed with Russian experts. Instead of the traditional arc starting method, electromagnetic arc is used to form plasma arc spots on the surface of the target and burn evenly on the whole surface of the target until the contact of the arc starting device is reached. The arc starting contact of the new electromagnetic multi arc target is close to the bottom of the target, thus ensuring the utilization rate of the target material more than 80%.

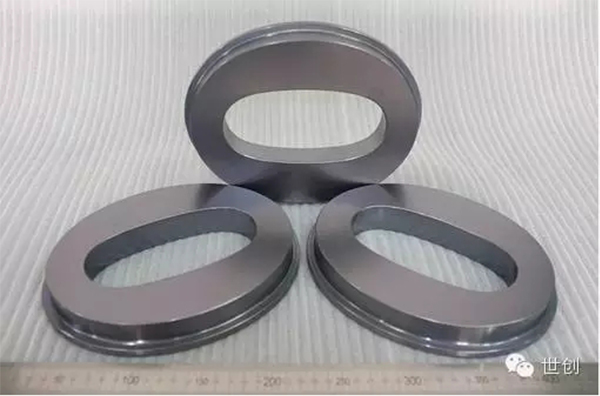

Target material size change before and after use

“STRONG coating machine is not only a device, it is our pursuit of perfection!”

Since winning the bid of a company in Xi'an and a company in Wuxi in 2015 and 2018, STRONG TECHNOLOGY signed the supply contract of heat-resistant coating machine and equipment with a company in Shaanxi again in November 2019. This fully shows that the coating machine of STRONG has gradually opened up a situation in the field of aeroengine. At present, scientific research and technical personnel of STRONG are working in this field to make this equipment continue to carry forward in China's aviation engine industry.

To learn more, click on the link below

STRONG TECHNOLOGY coating machine net

電話:0757-2332 2638

傳真:0757-2332 2619

地址:佛山市順德區(qū)陳村鎮(zhèn)石洲工業(yè)區(qū)30號(hào)

備案號(hào):粵ICP備09051653號(hào)